The European Directive 2006/42/EC, also known as the Machinery Directive, is a significant legislation of the EU that regulates the field of machine safety and occupational health. It was developed to ensure a high level of product safety for machinery in the European market while facilitating the free movement of goods within the EU.

The Machinery Directive 2006/42/EC is not a regulation in the strict sense but a directive. This means that it must be transposed into national law by the member states. For example, in Germany, this is done through the Product Safety Act and the Machinery Ordinance.

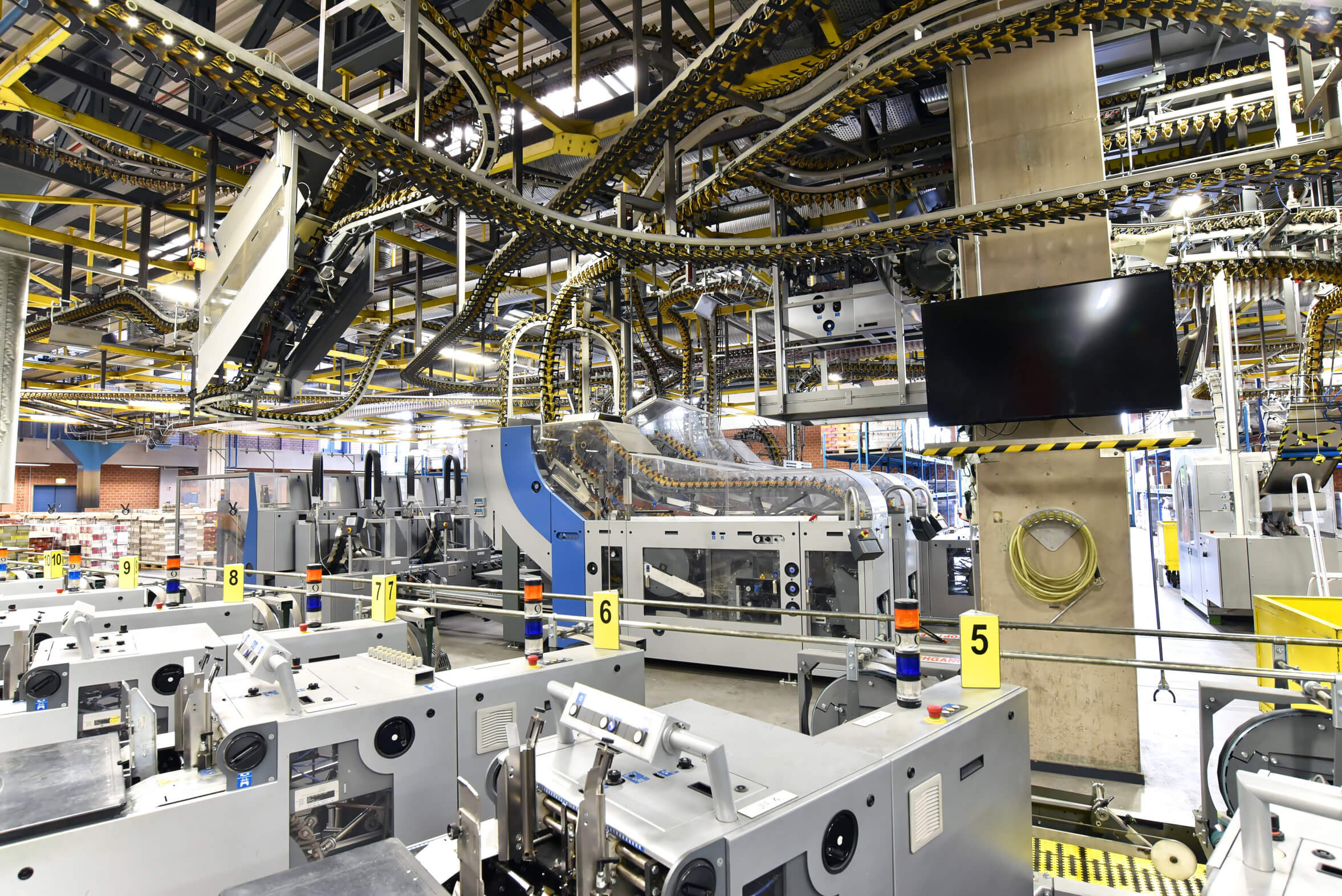

The Machinery Directive establishes fundamental requirements for machines to ensure the safety of individuals who come into contact with them. It applies not only to industrial machinery but also to everyday objects such as household appliances, tools, or toys that have a specific mode of operation.

An important aspect of the Machinery Directive is the risk assessment. Manufacturers must conduct a comprehensive analysis to identify potential risks and take appropriate measures to mitigate them. This may include the application of relevant standards mentioned in the Machinery Directive. Standards are technical documents that define requirements, procedures, and guidelines for specific products or services.

Furthermore, the Machinery Directive stipulates that machines must be affixed with the CE marking to demonstrate their conformity with the requirements. The CE marking is a symbol indicating that the product complies with the applicable European regulations and can be freely marketed in the European Economic Area.

The Machinery Directive 2006/42/EC is of great importance in ensuring a uniform level of safety for machinery in the EU. It contributes to reducing occupational accidents, improving occupational health protection, and safeguarding consumers from potential hazards. By establishing clear requirements and procedures, the directive also provides manufacturers with a solid foundation for designing and distributing safe machines.

Overall, the Machinery Directive 2006/42/EC represents an important legal framework that ensures the safety of machinery in Europe and contributes to the harmonization of the internal market.