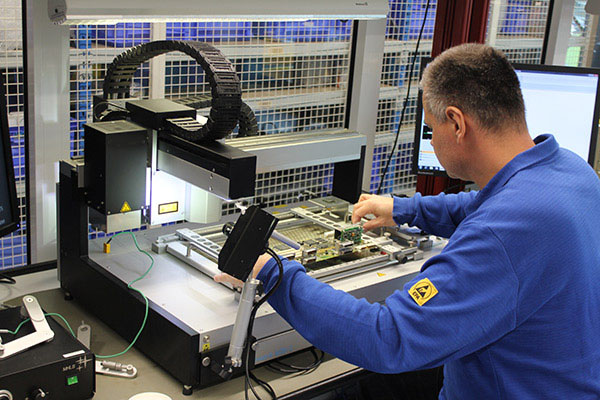

The decision between product overhaul and the new purchase of industrial electronics can play a significant role for companies in efficiently managing their equipment and optimizing budgets.

1. Cost: An essential factor in the choice between overhaul and new purchase is often the financial aspect. Product overhaul can be a cost-effective alternative to buying new. The costs for overhauling are typically lower than purchasing a brand-new device. This can be particularly advantageous when the company has a limited budget or when acquiring new equipment is financially infeasible.

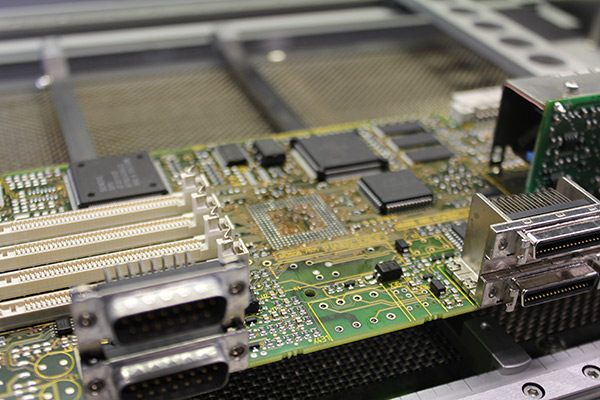

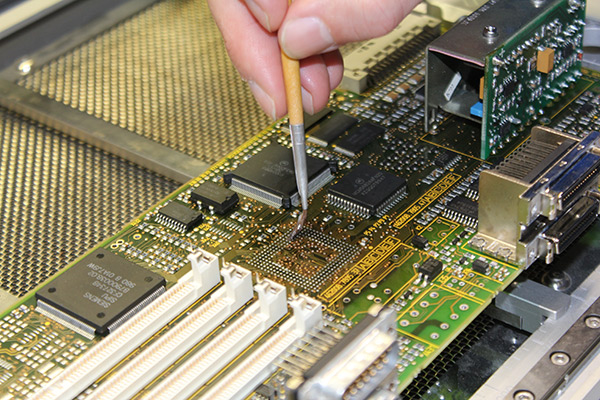

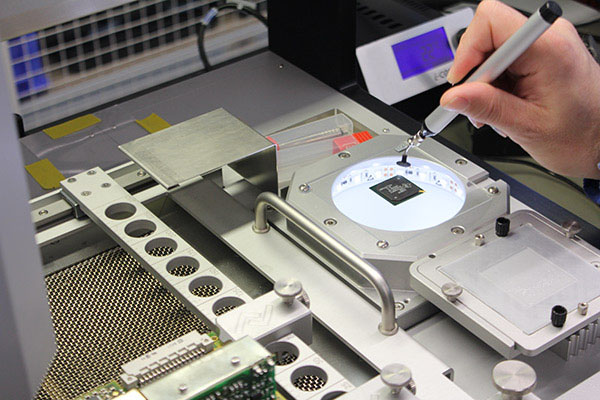

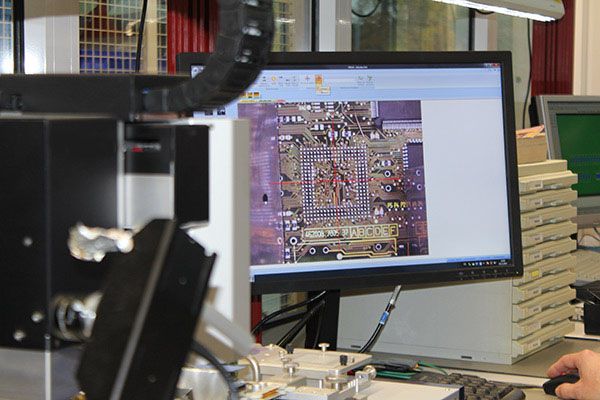

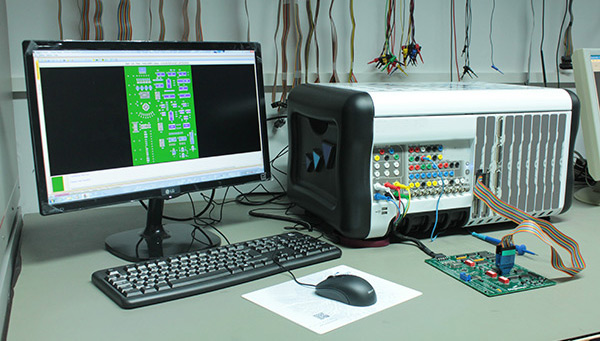

2. Performance and Functionality: With a new purchase, companies can obtain the latest technology and advanced features. New devices often offer improved performance and efficiency. However, a well-executed product overhaul can significantly enhance the performance and functionality of older devices, making them nearly equivalent to new ones but at a fraction of the cost.

3. Delivery Times and Availability: Purchasing new industrial electronics may involve longer delivery times, especially if specific customizations or tailor-made solutions are required. In such cases, product overhaul may be the faster option as replacement parts are usually more readily available. This is particularly important when minimizing downtime is crucial to ensuring smooth business operations.

4. Environmental Friendliness and Sustainability: Product overhaul promotes sustainability and environmental protection as it helps reduce electronic waste. By reusing and refurbishing industrial electronic products, companies can make a positive contribution to the environment and fulfill their ecological responsibility.

When is the overhaul of industrial electronics the better choice for CNC, PLC, and robotics?

-

Budget constraints: When the company operates with limited financial resources and still aims to improve the performance of its equipment, product overhaul is the most economical option.

-

Specialized equipment: If the company requires specialized equipment that is not readily available in the market, overhaul may be the only way to extend the lifespan of this equipment.

-

Historical significance: In some cases, the equipment may hold special historical or sentimental significance for the company. Overhaul allows the continued use of this valuable equipment instead of replacing it.

-

Short-term solution: If the equipment temporarily fails and an urgent, quick solution is needed, overhaul can enable rapid reactivation.

Overall, the decision between product overhaul and new purchase depends on various factors, such as budget, equipment requirements, environmental considerations, and time constraints. A well-informed evaluation of these factors will enable companies to choose the best option to efficiently and cost-effectively manage their industrial electronics.