Programmable logic controllers (PLCs) are essential components in automation technology and play a crucial role in controlling and monitoring industrial processes. Their purpose is to coordinate complex sequences to ensure efficient operation of machines and systems. The significance of PLC control lies in its ability to execute precise commands to automate and optimize processes, leading to increased productivity, quality, and safety.

Structure and Operation

A PLC essentially consists of a central control system, which comprises a powerful controller. This controller serves as the brain of the PLC and is connected to various sensors and actuators. Sensors capture information about the current state of a machine or process, such as temperature, pressure, or position. The captured data is analyzed by the controller, and based on this analysis, corresponding control commands are sent to the actuators. Actuators are responsible for carrying out physical actions, such as turning motors, valves, or pumps on and off.

Programming

Programming of the PLC control is done in a specialized programming language tailored to the logic and structure of automation processes. A common programming language for PLC control is, for example, the international standard IEC 61131-3. This programming language enables engineers to define logical connections, conditions, and sequences to implement the desired control operations. Programming can be done either directly on the controller or through special software that allows graphical programming.

Applications

PLC control finds diverse applications ranging from manufacturing industries to power supply and building automation. In manufacturing industries, PLC control is used to automate and optimize production processes. It enables control of conveyors, robots, assembly lines, and other production facilities. In power supply, PLC control is employed to monitor and control power grids, power plants, and renewable energy systems. In building automation, PLC control is used to regulate and optimize heating, ventilation, air conditioning, and other systems in buildings.

Modular PLC Systems

A development in PLC control is the introduction of modular PLC systems. These systems allow the distribution of control functionality into different modules that can be added or removed as needed. This enhances the flexibility and scalability of PLC control, particularly beneficial in complex applications. Modular PLC systems provide the capability to adapt control functionality to the specific requirements of a facility and enable efficient maintenance and system expansion.

Summary

Programmable logic controllers are indispensable tools in automation technology. They enable the control and monitoring of industrial processes through the use of sensors, actuators, and a powerful controller. Programming of PLC control is done in a specialized programming language, while modular PLC systems offer flexibility and scalability. With their diverse applications in manufacturing industries, power supply, and building automation, PLC controls significantly contribute to process efficiency enhancement and optimization.

Basic Equipment of a Programmable Logic Controller (PLC)

The basic equipment of a programmable logic controller (PLC) consists of various modules working together to ensure control functionality. Key modules include:

Input Process Image

This module is responsible for capturing the current state of the input signals of the PLC. Sensors and switches provide these signals, which can include information about temperatures, positions, or switch positions, for example. The input process image allows the PLC to understand the current state of monitored processes.

Output Process Image

This module is connected to the actuators and controls the output signals of the PLC. Actuators can be, for example, motors, valves, or lights. The output process image enables the PLC to generate the corresponding control signals and pass the desired actions to the process.

Arithmetic Logic Unit (ALU)

The ALU is the central element of the PLC and performs calculations and logical operations according to the program code. It interprets the entered control logic, executes the necessary operations, and generates the corresponding control signals for the actuators.

Control Unit

The control unit synchronizes and coordinates the execution of commands in the ALU. It ensures that the commands are executed in the correct order and that the necessary control signals are sent to the actuators at the right time.

Memory

The memory is an important module that contains the program code, control logic, and data during the operation of the PLC. The memory allows storing the program code and data for retrieval and updating at any time.

Flag

Flags are special memory areas used for temporary storage of data or intermediate values. They serve as variables in the control logic and can contain states, counters, or error codes, for example.

Address Registers

The address registers contain information about the memory addresses where the data and commands are stored. They enable access to specific memory areas and facilitate communication between the various modules of the PLC.

Accumulator

The accumulator is a register used for performing arithmetic operations. It serves as temporary storage for intermediate results and enables the execution of mathematical calculations in the ALU.

These modules constitute the basic equipment of a PLC and work together to interpret control logic, process input signals, generate output signals, and execute the desired automation process. Each module fulfills a specific function and contributes to the efficient control of machines and systems.

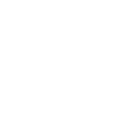

![[Translate to English:] SPS - Unser Portfolio - Weitere Hersteller - BVS Industrie-Elektronik [Translate to English:] SPS - Unser Portfolio - Weitere Hersteller - BVS Industrie-Elektronik](/fileadmin/user_upload/Geschaeftsfelder/SPS/UnserPortfolio-WeitereHersteller_sps.png)

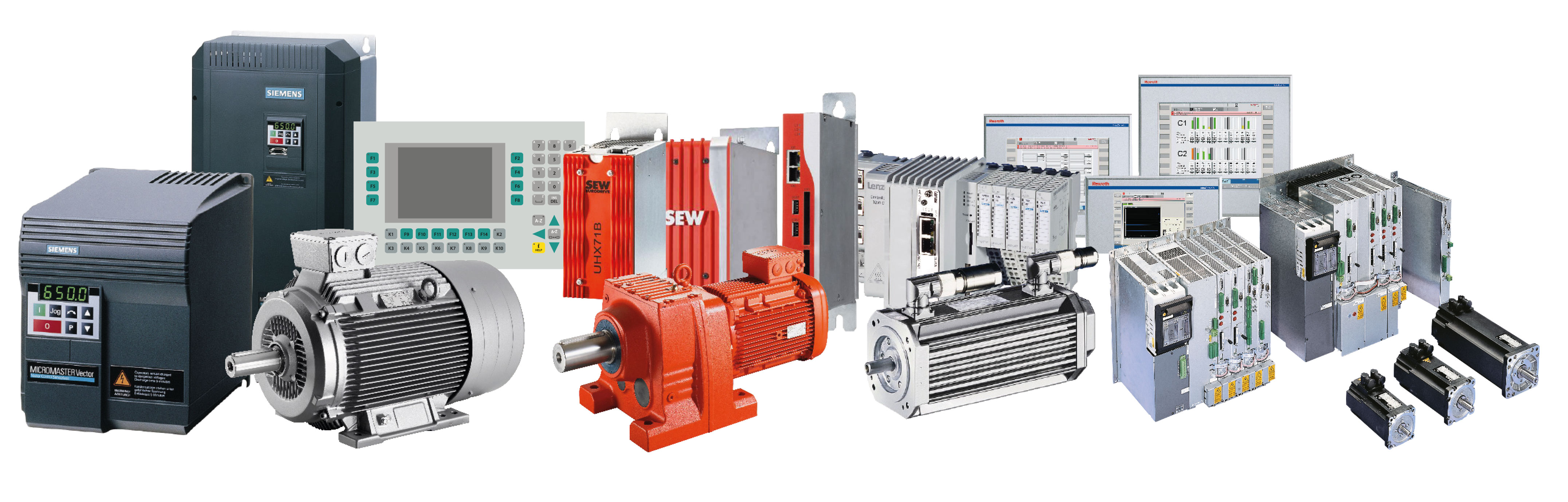

![[Translate to English:] SPS-Steuerungstechnik [Translate to English:] SPS-Steuerungstechnik](/fileadmin/user_upload/Geschaeftsfelder/SPS/SPS-Steuerungstechnik.png)

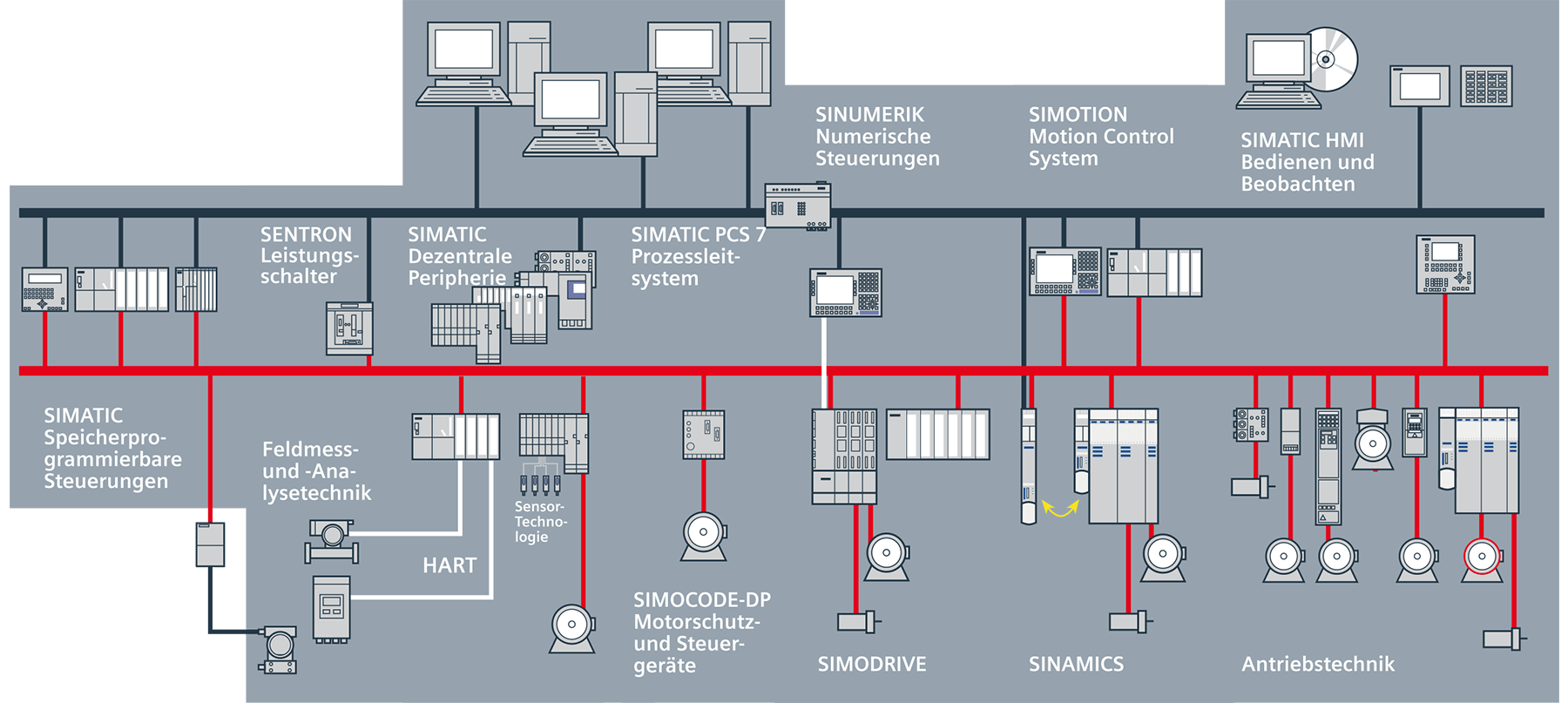

![[Translate to English:] HMI-Baugruppen [Translate to English:] HMI-Baugruppen](/fileadmin/user_upload/Geschaeftsfelder/SPS/hmi-baugruppen-bvs-cnc.png)

![[Translate to English:] IPCs-Programmiergeräte [Translate to English:] IPCs-Programmiergeräte](/fileadmin/user_upload/Geschaeftsfelder/SPS/SPS-IPC-Programmiergeraete.png)

![[Translate to English:] Antriebstechnik [Translate to English:] Antriebstechnik](/fileadmin/user_upload/Geschaeftsfelder/SPS/SPS-Antriebstechnik.png)

![[Translate to English:] herstellerübergreifendes Portfolio - BVS Industrie-Elektronik [Translate to English:] herstellerübergreifendes Portfolio - BVS Industrie-Elektronik](/fileadmin/user_upload/Unternehmen/Vorteile/BVS-Verfuegbarkeit/austauschlager-icon-bvs-cnc.png)

![[Translate to English:] zugelassene Komponenten - BVS Industrie-Elektronik [Translate to English:] zugelassene Komponenten - BVS Industrie-Elektronik](/fileadmin/user_upload/Unternehmen/Vorteile/BVS-Reparatur/austausch-verschleiss-bvs-cnc.png)

![[Translate to English:] Reduktion von Maschinenausfällen und deren Folgekosten - BVS Industrie-Elektronik [Translate to English:] Reduktion von Maschinenausfällen und deren Folgekosten - BVS Industrie-Elektronik](/fileadmin/user_upload/Unternehmen/Vorteile/BVS-Reparatur/ecofit-icon-bvs-cnc.png)

![[Translate to English:] Maschinenrichtlinienkonforme Reparatur - BVS Industrie-Elektronik [Translate to English:] Maschinenrichtlinienkonforme Reparatur - BVS Industrie-Elektronik](/fileadmin/user_upload/Unternehmen/Vorteile/BVS-Reparatur/reparatur-icon-bvs-cnc.png)

![[Translate to English:] Verwendung zugelassener Komponenten - BVS Industrie-Elektronik [Translate to English:] Verwendung zugelassener Komponenten - BVS Industrie-Elektronik](/fileadmin/user_upload/Unternehmen/Vorteile/BVS-Reparatur/verwendung-zugelassener-komponenten-bvs-cnc.png)

![[Translate to English:] Original-Teststände - BVS Industrie-Elektronik [Translate to English:] Original-Teststände - BVS Industrie-Elektronik](/fileadmin/user_upload/Unternehmen/Vorteile/BVS-Reparatur/belastungstests-icon-bvs-cnc.png)

![[Translate to English:] Schnelle Lieferservices - BVS Industrie-Elektronik [Translate to English:] Schnelle Lieferservices - BVS Industrie-Elektronik](/fileadmin/user_upload/Unternehmen/Vorteile/BVS-Service/kostenlose-lieferung-icon-bvs-cnc.png)

![[Translate to English:] DMSZ [Translate to English:] DMSZ](/fileadmin/user_upload/Qualitaet/dmsz-kombilogo-weiss-DE.png)